Research Project Full Title: Separation of Insoluble Oil from Water with a Hydrophobic Hollow Fiber Membrane Contactor

Research Project Full Title: Separation of Insoluble Oil from Water with a Hydrophobic Hollow Fiber Membrane Contactor

Principal Investigator(s): Frank Seibert (SRP), Lynn Katz and Kerry Kinney

Researchers: Aurore Mercelat

Sponsor(s): Suez International, 3M, NLV

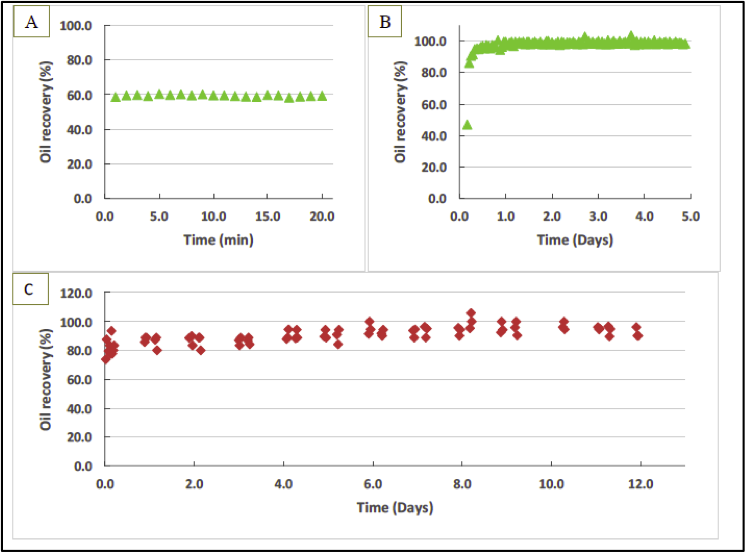

Full Abstract: Efficient oil-water separation is important in a wide range of industries. Treatment of produced water, oil spills and algal oil, for instance, require technologies capable of withstanding variable feeds and removing micron size oil droplets while maintaining long term performance. In this study, a novel membrane coalescence process is evaluated where oil is permeated across the membrane while water is retained. The fundamental mechanisms and key process parameters controlling the separation of oil and water in a hydrophobic hollow-fiber membrane contactor are characterized. Two oil concentration regimes were identified and shown to be controlled by different mechanisms. In this process, the oily aqueous feed is pumped into the shell-side of the membrane while controlling a shell side pressure greater than the fiber pressure. For high oil feed concentrations above 40% (v/v), increases in transmembrane pressure, residence time, and temperature increase oil flux across the fiber walls. However, for dilute mixtures (less than 2% (v/v)), experimental results indicate that an increase in transmembrane pressure and temperature lower oil flux. The design of the membrane hollow fiber contactor allows internal coalescence of oil droplets on the fiber surface followed by oil permeation due to the transmembrane pressure while maintaining water rejection. Experimental results suggest that the formation of an oil film on the fiber walls is necessary to provide adequate area for coalescence. On-going research is focused on evaluating the impact of suspended solids, inorganic fouling and interfacial tension.